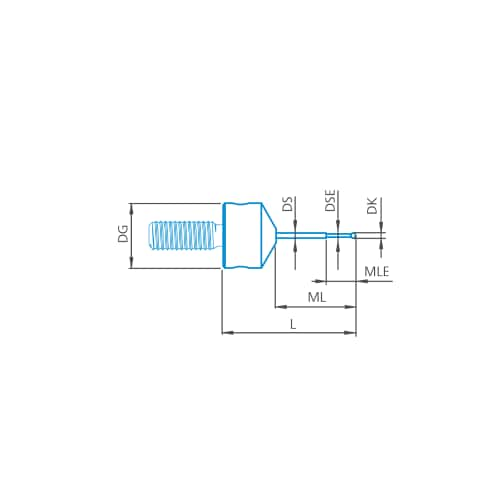

M5, long threaded styli, stepped, ruby sphere, tungsten carbide shaft

Stylus stepped M5x12,5, DK1 L22.5

600342-8254-000

Long threaded styli enable the assembly of discs and star elements with groove and clamping disc. M5 thread for VAST active scanning sensors.

- With longer thread for fastening disc and star elements

- Spherical styli have the same probing behavior in every direction

- Ruby is the most common sphere material

- Ruby sphere available from 0.2 up to 12 mm

- Tungsten carbide shaft with high rigidity

- Higher stability through stepped shaft

- Proven ZEISS quality through high-end manufacturing

- Product Type

- Stylus

- Connection Type

- M5x12,5

- Length (L)

- 22.5 mm

- Ø Body (DG)

- 11.0 mm

- Ø Shaft (DS)

- 1.0 mm

- Ø Sphere (DK)

- 1.0 mm

- Measurement Length (ML)

- 13.5 mm

- Stylus Type

- Stepped

- 2nd Ø Shaft (DSE)

- 0.8 mm

- 2nd Measurement Length (MLE)

- 5.0 mm

- Stylus Tip Geometry

- Sphere

- Stylus Tip Material

- Ruby

- Shaft Material

- Tung. Carb.

- Application

- Tactile

- Weight

- 6.0 g

Product note

Depending on the material of the stylus and the workpiece, wear or material deposits may occur. Therefore, regularly check your styli under a microscope and remember to clean them or replace them if damaged. Depending on the type and degree of contamination, a wide range of cleaning agents are available for cleaning. ZEISS application engineers recommend stylus cleaning wipes or microfiber cloths.